Solutions for process automation and industrial systems

Operational efficiency, reduced costs, increased productivity

In order to be profitable, any company in the industrial sector knows that this field requires constant quality in the production of products at a competitive price. To meet this challenge, players in the industry have solutions for automating industrial processes and systems.

These solutions support an increase in product quality, reliability and production rate, while reducing design and production costs through the adoption and integration of new technologies and services.

Industrial processes and systems are automated according to the company's needs and budget with the opportunity for scalability as the project evolves.

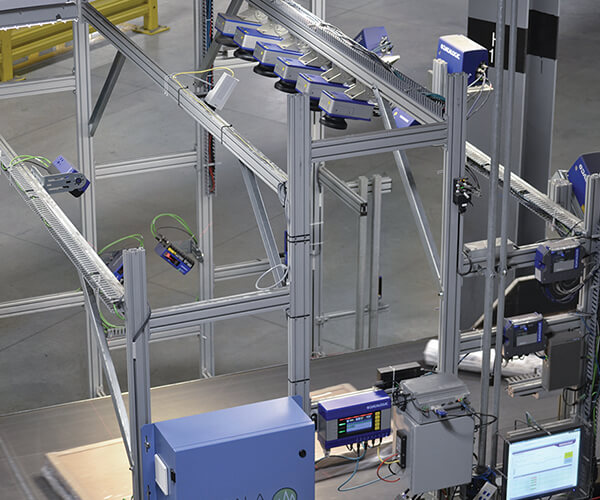

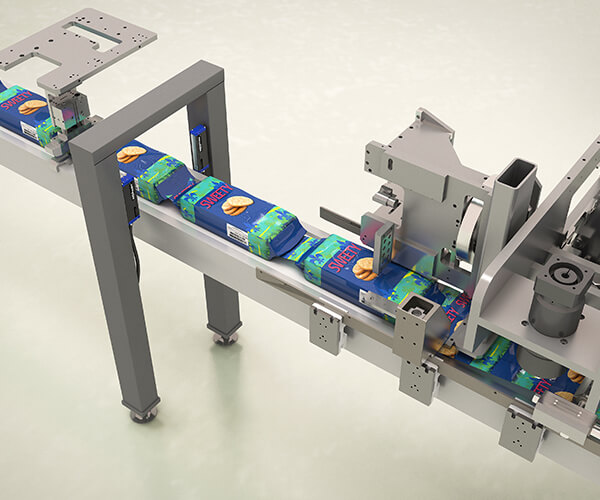

Modern equipment and technology for scanning, monitoring, labelling, laser, or jet marking.

Automation solutions are tailored according to volume, destination, best practice, quality control, product profile and logistics elements.

Complete production lines equipped with scanners and scanning modules, monitors, labelling, sensors, new scanning modules, laser or jet marking.

If the first industrial revolution took advantage of mechanization and steam power and the second industrial revolution was defined by mass production, assembly lines and electricity, Industrial Revolution 4.0 is defined by cyber-physical systems, IoT (Internet of Things), cloud and AI (Artificial Intelligence).

When an industrial company adopts the 4.0 methodology (digitization, automation, use of the advantages of big data, data analytics, artificial intelligence, and Cloud technology together with a complex and flexible ecosystem of industry-specific equipment), it enjoys full connectivity, pervasive transparency and intelligent programming of all processes.

These benefits translate into increased productivity, faster and more agile processes, reduced costs (elimination of material waste, fewer manual operators), a safer and more motivating work environment through professional development opportunities (training and collaboration programs), improved communication between teams and departments.

Many companies face the problem of successfully scaling industrial automation. One-off, isolated projects and a lack of a company-wide automation strategy make it almost impossible to adapt to a constantly changing environment.

Industrial process and system automation solutions have two key advantages to solve this challenge. The first is the scalability of the solutions: organizations can change automation capacity and resource allocation in a fast and dynamic way.

And the second major advantage is intuitive applications for quick deployment. Simple to use, they accelerate the uptake rate and deliver visible results from the early stages of the project.

The approach empowers the teams, supports company-wide implementation and automation across all processes.

To grow, industrial companies are constantly looking for new ways to increase precision, speed, and financial efficiency. Regardless of the sector, industrial companies must continually adapt to market demands and new standards of quality and speed. Automation solutions respect and align with this trend, adapting to the specifics of each company.

Innovations in artificial intelligence and sensor technology allow these solutions to adapt at a much faster rate than traditional operators, variable tasks, and changes in the working environment. This adaptability leads to improved quality in all sectors, and programming and calibration options allow solutions to be quickly and easily integrated into different industrial environments.

Automation solutions improve the quality of industrial processes and final products by supporting the creation of an environment where everything is streamlined at similar or even lower costs compared to pre-automation. The advantages of this environment are:

Elimination of human error: human personnel cannot guarantee zero errors in processes and checks, while automation turns them into thoroughly checked processes.

Improved consistency and accuracy: an automated process will run in the same way and with the same attention to detail every time, guaranteeing consistent quality products.

Troubleshooting: Automation solutions continuously monitor all equipment and processes and signal any potential hazards that may cause disruptions in a timely manner.

One of the main advantages for automation solutions is their flexibility and how this adds value when it comes to increasing production capacity.

By integrating several pieces of equipment specifically designed to optimize work points (laser or jet engravers, unattended scanning systems, machine vision systems, sensors, power desks, safety light curtains, safety laser scanners, etc.) industrial companies enjoy a perfect balance of manual labour – automated systems and stand out in terms of productivity, profit, and traceability.

© IT Genetics . All rights reserved.