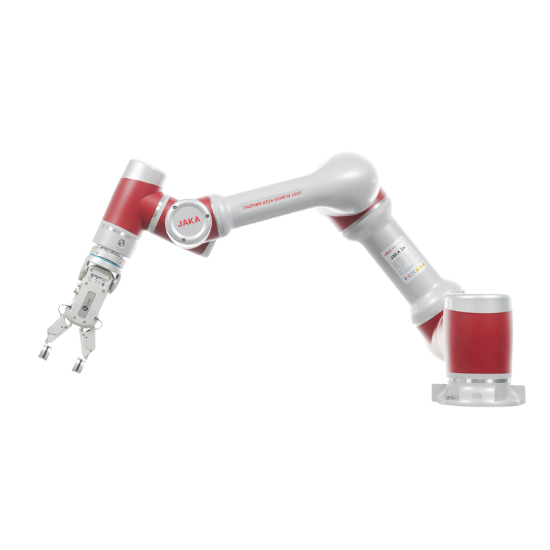

cobots set your business in motion.

© IT Genetics 2024. All rights reserved.