with end-to-end manufacturing line management solutions.

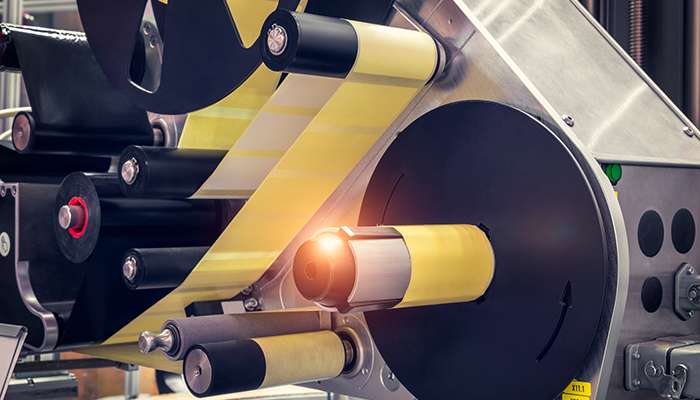

Ensure production traceability by identifying raw materials and finished products using automatic scanning and labeling, in accordance with the legislation in force.

Easily recall products with manufacturing defects from the market.

Gain maximum visibility throughout the entire production chain with automatic labeling, scanning and wireless and IT&C infrastructure.

Reduce fulfillment risks using an inventory management solution.

Automate all repetitive processes with the help of collaborative robots.

Increase production speed and the quality of finished products by eliminating human errors.

Allow employees to engage in more creative work, while repetitive and tiring work is handled by cobots.

Avoid work accidents by having cobots perform hazardous tasks.

Automate industrial processes or systems according to your requirements and budget.

Increase the quality of your products with modern equipment and technologies: scanning, monitoring, labeling, laser or inkjet marking.

Automate industrial processes and systems based on industry and production capacity.

Increase production capacity through manufacturing lines while keeping the same investments in human resources.

Collect real-time production data, monitor each production line and ensure maximum productivity.

Data collection helps companies increase production through industrial automation.

Avoid unforeseen malfunctions by collecting data on equipment condition and latest maintenance check.

Create an unique equipment mix for your business: scanners, printers, software applications, central displays and HMI equipment.

Easier management of raw material stocks, production processes and finished goods.

Eliminate human errors and easily centralize data with digital solutions.

Receive replenishment notifications when stocks are low or depleted.

Display inventory management on digital monitors and provide real-time production and purchasing information to your team.

Ensure an easy and efficient inventory process for your goods, including fixed assets.

Perform a maintenance management analysis at any time, based on real-time data collection.

Eliminate human error and increase process efficiency with barcodes, RFID tags, allocated series and images.

Label each type of product for quick identification and location and add all the information you need.

Choose the right labeling solution for your products: paper product or traceability labels, textile labels, PVC plastic labels or cardboard tags, identification bracelets, RFID antenna labels.

With the help of our solutions you’ll meet all the criteria and regulations from authorities, ensure traceability in production, reduce long manufacturing time and offer a personalized branded design for the products in your portfolio.

Use efficient solutions for automated direct part marking on any material, including plastic or metal.

Use compact printing and part marking solutions, equipped with software systems and equipment that is easy to install and use to automate processes and ensure a continuous flow on your production line.

Discover the advantages of state-of-the-art marking technologies such as Thermal Inkjet (TIJ) and Continuous Inkjet (CIJ).

Ensure good quality management with scanning equipment that uses high-precision sensors that identify any defects before the products are launched on the market.

Decrease the number of faulty products by identifying production errors along the way, at each stage.

Reduce the return rates, eliminate human errors from quality control processes so that you can improve your brand name on the market and differentiate yourself from the competition.

Add a weighing system to this solution to easily determine if the packages, boxes, pallets or batches are complete.

Easily and efficiently manage equipment maintenance: always know what equipment was checked, when and by whom.

Avoid errors or quality loss due to defective equipment by tracking the maintenance management analysis.

Digital maintenance analysis: managers and operators are automatically notified and receive their up-to date tasks or information.

Enjoy the benefits of remote service. In the absence of an accredited specialist, the internal team can ensure the maintenance or repair of faults through dedicated schemes and software.

Maintain control of problems and incidents with sensors and scanning equipment able to detect faults and send real-time alerts.

Displays problem and incident notifications on digital screens, remotely visible in the production space, and decreases intervention time.

Avoid stopping production due to lack of consumables by visual indicators that signal ahead of time to the production team that the equipment is running out of consumables.

Decrease delays and deliver on time with stock depletion alerts.

Specialized consulting

We work with you to go through the digitalization process as easily as possible. We help you decide on the solutions you need, taking into account the industry and your plans for growth.

Optimization plan

We use our know-how and extensive practical experience to find the optimal system for you. We assemble the hardware & software solutions and choose manufacturers based on your budget.

You have an account manager specialized in your business vertical and also knows your account history, the solution being used and you will be in direct contact in order to deal with any issue that might arise.

Qualified specialists

You will interact with certified consultants with extensive experience in developing AIDC & POS solutions, well-known in the field for their proactivity and level of expertise.

We are right there with you by phone and online 24/7 and we travel wherever and whenever you need technical support to integrate the proposed solutions.

Installation

You receive professional support with installing the equipment, anywhere in the country, to ensure that you fully understand the proposed solutions and help make your daily activity as easy as possible.

Maintenance

You can always opt for a technical support subscription through which you will always have a specialist ready to intervene for maintenance sessions, customizations, tests, resets or complex trainings.

Authorized repair service

You get a diagnosis and a quick solution to any problem that pops up. You have access to strategic partnerships with the main manufacturers in the industry (Zebra, Citizen, Honeywell, Datalogic) and you can benefit from special contracts to extend the warranty.

© IT Genetics 2024. All rights reserved.